Cricket, une technologie permettant l'injection à dosage incrémental

Robert Liddell

Product Development - UX

La version française n’est pas disponible.

Some indications require precise dosing accuracy. However, standard syringe volume markings can be tricky to read, and it is easy to slip-up on occasion and push the plunger a bit further than intended. Our incremental injection technology aims to resolve this issue.

Understanding the user

The best way to hit the ground running is by sitting down with real-world product users and watch them work. We noticed that professionals in the dermatology industry would use a very small dose of toxin for a specific area, then move to another area and inject the same dose. This is particularly difficult with doses under 20 μL. It became evident that a device that delivers such low dose increments with high precision would be greatly beneficial to these professionals.

Defining the project

As soon as we started this project, we knew that consistently dispensing such small volumes would be a technical challenge, so we started looking at other tools known for their reliable micro-incremental mechanisms. We then decided to divide this challenge into two separate objectives. First, we had to find a way to precisely control the piston displacement for a given actuation. Second, we wanted to provide the most comfortable manipulation position by maintaining an optimal physical distance between the user’s hand and the injection location. While the former would require the development of a unique micro advancing mechanism, the latter would be conquered through ergonomics.

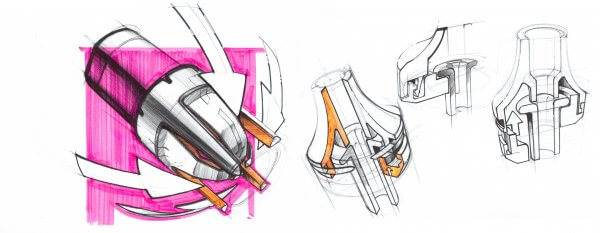

Developing the concept

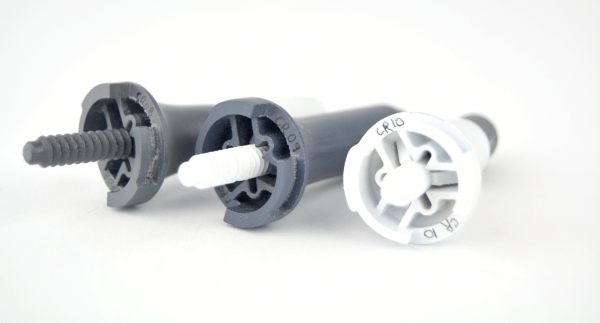

Our team of engineers and designers got to work aiming to develop a mechanism capable of reliably dispensing increments of 15 μL from a standard 1 ml long pre-filled syringe. Our first prototypes could only manage 50 μL increments but did so reliably. At that moment, we knew we were onto something and that we could reach our goal by fine-tuning our concept.

After several prototype iterations, we were able to come up with a device that reliably delivered 15 μL increments. The mechanism we developed uses a micro-grooved plunger rod and two sets of independent compliant mechanisms. The upper advancing mechanism advances the plunger rod to a pre-determined distance, while the lower retaining mechanism holds the plunger rod in place as the advancing mechanism returns to its initial position.

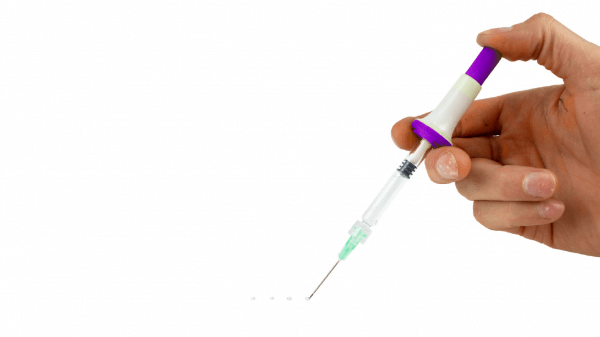

Perfecting the solution

Once we achieved a reliable micro incremental mechanism, we began tackling our second objective: to package our mechanical solution into a device that is intuitive and comfortable to use. No one is better suited for judging what is appropriate and suitable than the individuals who use these devices on a daily basis. Thanks to our years of experience in handheld device development and the key industry professionals who provided their time to share valuable feedback with our team, we were able to create a unique solution for incremental micro-injections.

This project case study demonstrates our team’s ability to combine engineering and industrial design and turn technically complex mechanisms into intuitive and ergonomic products. If you are interested in this technology, or if you have a project which requires developing a new medical device solution, get in touch with us!

Vous avez aimé cet article?

Nous aimerions avoir votre opinion.

Contactez-nous